Understanding Sintering Technology in Gear Production

Gears help machines turn, lift, or move things. Today, we explore sintering technology in gear production.

What is sintering? It is a way to make strong metal parts without melting them fully. Tiny metal powders are pressed together, then heated just enough to bond.

This method saves energy and material. It allows making complex shapes with precise sizes. Gears made this way can perform well under heavy load.

Students will learn how sintering works, why it matters, and where it is used. Let us dive into the steps, benefits, challenges, and examples to understand it better.

What Is Sintering Technology in Gear Production

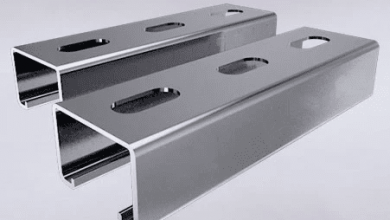

Sintering technology means using metal powders to create parts. First, powders are mixed into the correct proportions. Then they are shaped under pressure in a mold.

After molding, parts are heated below the melting point. Heat causes particles to bond together. This builds strength through shared surfaces. Pores (tiny holes) shrink, density rises.

Finally, gears are cooled gradually to avoid cracks. This process lets gear makers form precise shapes. It also reduces waste because there is less machining needed.

Sintering helps produce many gears quickly. It is useful for making gears that are light but still strong.

Key Steps in the Sintering Process

The sintering process has several big steps. Step one: choosing metal powders of good quality. Step two: blending powders, adding lubricants or binders.

Step three: pressing powder into gear molds. Step four: sintering in a furnace under controlled heat. Step five: cooling down parts slowly.

Step six: finishing steps like cleaning, sizing, or polishing. Each step must be precise and safe. The temperature must be just right. Pressure must be evenly applied.

Time must allow bonding without melting. Mistakes in any step give weak gears. Proper control yields gears that match the design exactly.

Materials Used in Sintering for Gears

Various metals and alloys work well in sintering for gears. Iron-based powders are common for their strength and cost. Sometimes copper is added to improve conductivity or wear resistance.

Nickel or chromium often improves toughness and rust resistance. Different powders have different particle sizes. Small particles pack better and sinter more uniformly.

Additives help reduce porosity or improve lubrication. Binders may temporarily hold powder shape during pressing. Lubricants help pressing molds to release parts.

All materials must be safe and clean. Proper choice of powders influences gear hardness and durability. So, the material mix is very important for gear performance.

Benefits and Advantages of Sintering Gears

Sintered steps give many good things. It uses less material waste than machining. It is faster to make many parts. Complex shapes are possible without heavy machining.

Gears can be lighter yet stronger. Costs drop when many gears are made. Precision is high; parts are consistent in size and shape. Noise and vibration are reduced because parts can be made smooth.

Fuel or energy savings happen if gears are used in machines. Repairs need less work if parts fit well. So overall, sintering gives efficiency, cost savings, and performance improvements for gear makers and users.

Challenges and Limitations in Sintering Technology

Despite many advantages, some challenges exist. Porosity might remain inside the metal after sintering. That weakens the gear under heavy load.

Heating must be uniform, or parts must not warp. Mold strength matters; molds wear out over time. Surface finish may need extra polishing.

Joining with other parts might need machining. Some complex gear shapes are still hard to sinter perfectly. Costs for high-precision molds and furnaces are high.

Finding the right material mix takes time and testing. Also, quality control must be strict.

If any step fails, the entire batch may be wasted. Engineers must balance cost, speed, and strength demands.

How Companies Use Sintered Gears

Many companies use sintering to make gears for vehicles, machines, and tools. At Atlantic Sintered, Sintered Gears are manufactured in Massachusetts using powder metallurgy. They build gears for EVs, robotics, agriculture, and automation.

Parts go into transmissions, gearboxes, axles, and small motors. Because sintered parts need less machining, companies save time and money. They can ship gears faster.

Clients get parts that last long under tough conditions. Industries like medical devices also use these gears for quiet, precise movement.

Even in farming machines, strength and cost matter. So companies apply sintering across many fields.

Quality Control and Testing in Sintering

Quality control ensures gears are safe and work well. Testing includes measuring gear size, tooth profile, and pitch. Also checking hardness and density.

Microscope tests may check internal pores or bonding. Machines called metrology labs inspect parts. Hardness tests measure how well a gear resists wear.

Torque and fatigue tests show how the gear handles repeatedly turning loads. Surface finish is measured to see smoothness. If parts fail, they go back to be fixed or scrapped.

Certification ensures parts meet standards worldwide. This builds customer trust. Good QA reduces failures and accidents. Without strict testing, gears might break early.

Future Trends in Sintering Gear Technology

Engineers look for new ways to improve sintering gear making. One trend: improving density while lowering weight. Also, refining surface finishes so no extra polishing is needed.

New alloy powders will give more strength and corrosion resistance. Machines will heat more precisely, maybe with better furnaces or lasers. Shape-making tools (molds) will improve for finer details.

Simulation software will help predict warping or defects ahead of time. Also, combining sintering with additive manufacturing may open futuristic options. Sustainable practices will rise: using recycled powders or greener energy.

More automation will speed production and reduce errors. These changes will make gears better, cheaper, and more reliable.

Learn Sintering Technology in Gear Production

Understanding sintering technology in gear production helps you see how machines around you work. You learned what sintering is, how it is done, what materials are used, and why it is helpful.

You saw that there are challenges too, but companies use testing and good design to make strong parts. Trends will make sintering even better in the future.

Next time you use a bike, car, or robot, remember there may be sintered gears inside. They bring performance, precision, and savings.

Did you find this article helpful? If so, check out the rest of our site for more informative content.